Seatbelts were fastened, and the exit doors were closed and armed. But the door plug bolts on the mid-fuselage may not have been in the holes that were drilled for them. Inspectors found no evidence that the threads had ever been used.

The initial report on the Jan. 5, 2024 door plug failure on an Alaska Airlines flight says the door plug made a loud bang when it separated from Flight 1282, and crew in the cockpit reported their ears popped.

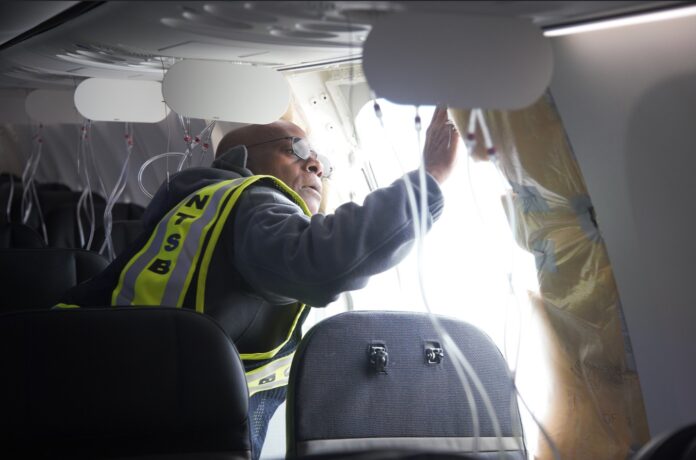

The report from the National Transportation Safety Board also says that the bolts that were to hold that door plug on the aircraft appear to have never been in place before flight. The aircraft had just come off the factory floor in October.

“Overall, the observed damage patterns and absence of contact damage or deformation around holes associated with the vertical movement arrestor bolts and upper guide track bolts in the upper guide fittings, hinge fittings, and recovered aft lower hinge guide fitting indicate that the four bolts that prevent upward movement of the MED plug were missing before the MED [mid exit door] plug moved upward off the stop pads,” the report says of investigators’ inspection of the door plug, which was found in a residential garden southwest of Portland not long after it fell from the jet that had been heading to Ontario, Calif. from Portland..

The 19-page report was issued a month and a day after the Jan. 5 mid-air incident that happened on Alaska Airlines Flight 1282, after which all Boeing 737-9 MAX jets were grounded for inspection and bolt-tightening. As of Tuesday, more than 90% of those jets are back in the air.

“The captain said that, while climbing through about 16,000 ft, there was a loud bang,” the report says. “The flight crew said their ears popped, and the captain said his head was pushed into the heads-up display (HUD) and his headset was pushed up, nearly falling off his head. The FO [first officer] said her headset was completely removed due to the rapid outflow of air from the flight deck.”

In a House committee today in Washington, D.C., Federal Aviation Administration Administrator Mike Whitaker said his agency is closely scrutinizing Boeing after the most recent incident. The FAA will have more boots on the ground monitoring production and manufacturing activities, he said.

Also, Spirit AeroSystems, which makes the fuselage for Boeing and which has taken responsibility for the blowout, made a decision to withhold financial guidance to investors and potential investors on its fiscal performance for this year until it finds its path, since the 727 MAX production has come to a pause at Boeing. Spirit depends almost exclusively on Boeing for its business model.

The Federal Aviation Administration is engaged in a “nose-to-tail, wingtip-to-wingtip inspection” of the 737 MAX processes at the Renton, Washington factory, and at Spirit AeroSystems in Wichita, Kansas.

Shares of Boeing Co. are down 20% since Jan. 6.